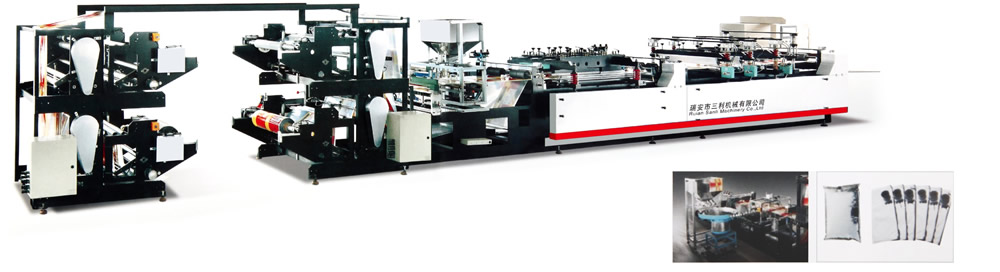

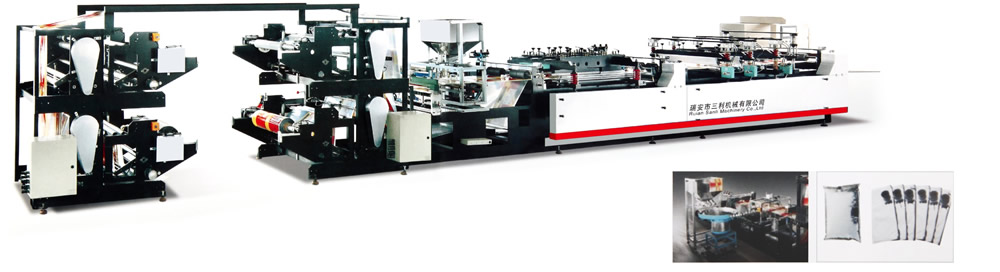

SLZD-700/1000/1100HZ Automatic Bag in Box Bag-making Machine

Function indicationWarping mode

Fabrication: Put the warp beam horizontally, with V fold support, andpneumatically lock.Control: Tension is automatically controlled byswimming roller, magnetic power brake, displacement sensor etc.Driving mode

Feeding traction: Driven by AC servomotor

Upper and lower sealing press: Driven by AC servomotorControl mode

Adopt the industrial control equipment, domestic displayerAdopts double pholoelectric controlFunctions

Temperature:0-300C .contact-free automatic control, CRT displaying.Automatic count: preseting is avalable.

Hole puncher for welding nozzle:1 Unit, It can move on all sides.Feeding unit for welding nozzle(vibrating tray):The vibration plateautomatically feed system of the nozzle, then by PLC centralizedcontrol positioning, hot pressure system to complete.

Punching device: time can be preset, continuous or interval punchingis available.

Working mode: printing. non-printing.

Mode of mutiple conveyances twice to six times conveyance.

Measurement for length; distance between color scale can be measuredphotoelectrically.

Message alert: lost of photoelectrically. lost of temperature, wrappingalarm, servomotor alarm and auto-switch off the machine.

|

Feed drive AC servo motor

|

7kw

|

|

Up and down sealing drive AC motor

|

3kw

|

|

Unwinding traction motor

|

4kw

|

|

Edge sealing device

|

12kw

|

|

Transverse heat sealing device

|

12kw

|

|

Control System and Others

|

3kw

|

|

Total power

|

Approx 38Kw

|

|

gas pressure

|

0.6Mpa (6kgf/cm)

|

|

Cooling water

|

Approx 15L/min

|

|

Dimensions (length x width x height)

|

15000 x 2000x 1900mm

|

|

machine weight

|

Approx 6000kg

|

|

Bag making speed

|

35 70pcs/min According material & Operating, The size of welding nozle)

|

|

Bag width

|

Max. Width1000mm

|

|

Bag length

|

10-500mm, when the set program is above 320mm, it will automatically change into multiple conveyances.

|